Introduction

Most small businesses trying to apply Lean for SMEs see it as a cost-cutting or corporate efficiency exercise – a way to do more with fewer people. That is where the misunderstanding begins.

Lean was never just a factory discipline; it was a philosophy of flow, waste reduction, and continuous improvement, regardless of company size.

The problem is – Lean was born in environments with full-time process teams, structured data, and steady resources.

For SMEs running on lean budgets and multitasking teams, that same playbook feels like overkill.

That is why Lean efforts often stall, even when the intent is right.

🟡 COSMOS Lean Clarity Series – Part 2

This article builds on Part 1, where we covered how lean team operations rely on SOPs, automation, and visibility instead of headcount. If you have not read that yet, start there…

it shows how to make Lean work with the team you already have.

➡ Part 1: How to Run Lean Team Operations – SOPs, Automations & Visibility

➡ Next: Part 3: Why Most Lean Projects Fail in SMEs (and How to Fix It)

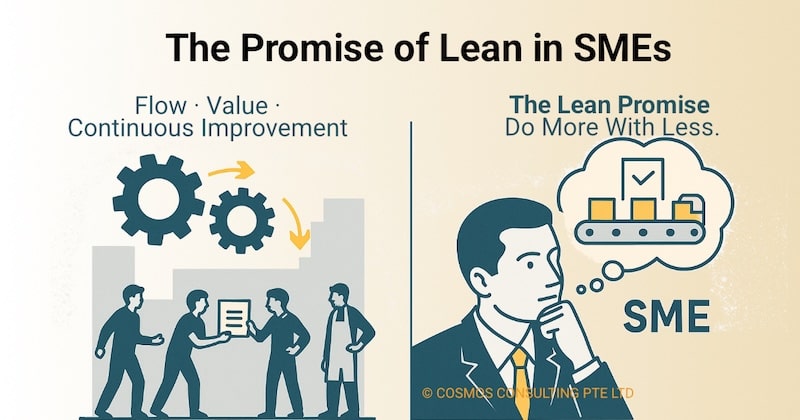

1️⃣ The Promise of Lean in SMEs and Why They Fell in Love With It

Lean Thinking, derived from Toyota’s Production System, was built on a beautiful premise: remove waste, focus on value, and empower people closest to the work.

For small businesses, that vision is irresistible. Who wouldn’t want a nimble, efficient team where every action adds value?

But here is the catch: Lean assumes a certain level of operational maturity – defined roles, stable processes, and visible data. Most SMEs don’t start there. They’re often running lean out of necessity, not by design.

According to the Lean Enterprise Institute, Lean Thinking focuses on value and flow – principles that the COSMOS 4S Systems Framework™ translates into SME practice.

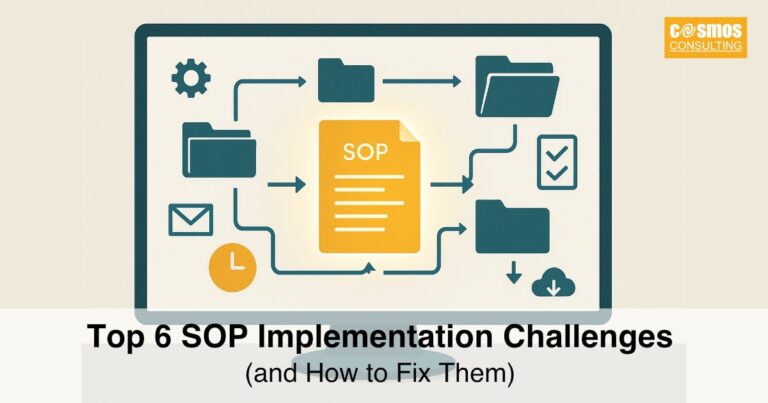

2️⃣ Where Lean Meets the SME Wall

In practice, small businesses hit barriers that Toyota never had to deal with:

- Limited structure: Roles overlap; no one truly “owns” processes.

- No time for documentation: SOPs feel like a luxury.

- Data chaos: Metrics live in spreadsheets — or worse, in people’s heads.

- Cultural fatigue: Teams equate Lean with “extra work” instead of clarity.

So while Lean’s intent is timeless, its implementation model is not built for small-team realities.

Lean in SMEs doesn’t fail because teams are careless; it fails because they start from a different place.

And that is where COSMOS 4S steps in, not as a replacement for Lean, but as its modern evolution.

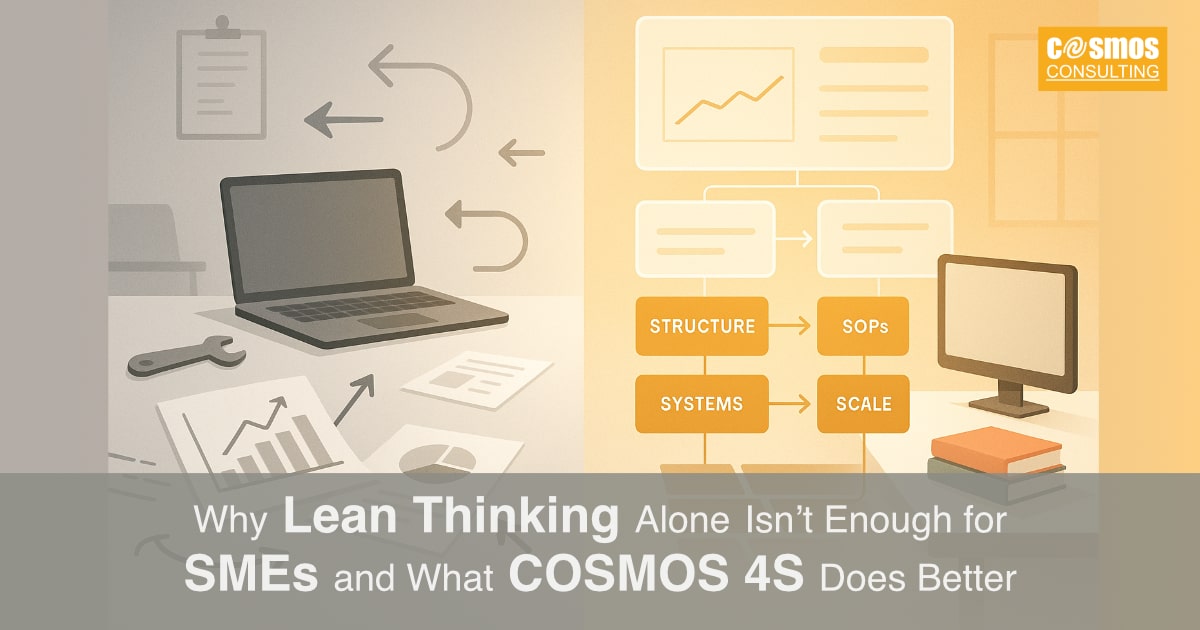

3️⃣ Why COSMOS 4S Does It Better – A Lean Evolution for Real SMEs

The COSMOS 4S Systems Framework™ doesn’t replace Lean; it translates it.

It turns Lean’s ideals into a usable roadmap for SMEs, introducing the one thing traditional Lean forgot – sequence.

Because without order, improvement doesn’t stick.

The COSMOS 4S Path:

- Structure → Clarify roles, responsibilities, and visibility.

- SOPs → Document the “how” behind daily work.

- Systems → Build lightweight tools and automations for visibility.

- Scale → Unlock growth capacity without chaos.

By following this order, SMEs achieve what Lean always promised: flow, accountability, and continuous improvement, but in a way that fits their size, pace, and reality.

Instead of expecting “continuous improvement” from a team still defining who does what, 4S starts with Structure – making ownership visible. Only then do SOPs and systems have something to hold on to.

Example:

A small packaging company once tried Lean 5S across its floor but couldn’t sustain it — every week, different people rearranged shelves and renamed zones. When we topped the COSMOS 4S layer onto their Lean 5S efforts, we began by mapping who owned which area (Structure) and documenting a single standard restocking SOP. Within two weeks, confusion stopped and visual order held — without another “Lean workshop.”

📂 Start Lean the right way.

Every sustainable Lean system starts with clarity. Get the SOP Starter Kit – the structure we use to stabilize teams before we optimize them.

Download the free SOP Starter Kit →

This sequence ensures Lean’s spirit, waste reduction, flow, and empowerment become achievable even for 10-person teams.

Instead of introducing Kanban boards or Kaizen workshops right away, 4S starts where most SMEs actually are: messy, overloaded, and under-documented.

SOP Starter Kit

A simple starter kit to help you document your first SOP with clarity, structure and confidence.

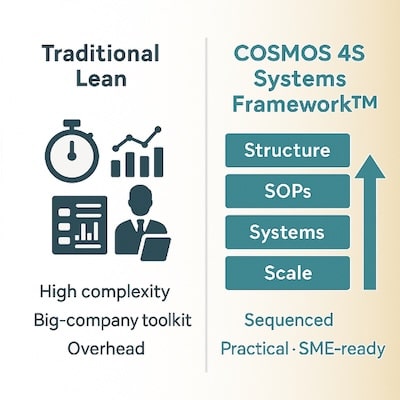

4️⃣ Lean Without the Overhead: How COSMOS 4S Converts Theory Into Practice

| Lean Principle | 4S Equivalent | Practical Outcome |

|---|---|---|

| Eliminate waste | Structure | Clear roles cut duplication |

| Standardize work | SOPs | Repeatable, quality-controlled execution |

| Continuous improvement | Systems | Visibility dashboards make progress measurable |

| Empower teams | Scale | Freed time → creative problem-solving |

Where Lean relies on formal systems, 4S achieves the same clarity with micro-systems – shared drives, simple trackers, and automations that teams can maintain themselves.

5️⃣ Clarity Before Complexity: The SME Advantage

Big firms chase efficiency; SMEs must chase clarity first.

Clarity creates rhythm, accountability, and momentum: the raw materials of Lean flow.

COSMOS 4S delivers Lean outcomes without corporate overhead:

- Visibility before velocity.

- Structure before strategy.

- Systems before scale.

That is the order that makes Lean stick.

Large enterprises use Lean to squeeze the last 2% of waste from stable systems. SMEs, on the other hand, are still trying to make those systems visible.

That is why clarity before complexity is a competitive advantage, not a delay.

Example:

A 20-person fabrication firm was chasing Lean KPIs like cycle time and OEE, but couldn’t explain how jobs actually moved from quotation to delivery. When they paused to document that flow and set up shared dashboards, they discovered that 40% of delays came from unclear approvals, not machinery. One visibility board solved what months of data analysis couldn’t.

COSMOS 4S gives SMEs a structure to see before they optimise. Because you can’t remove waste you can’t see.

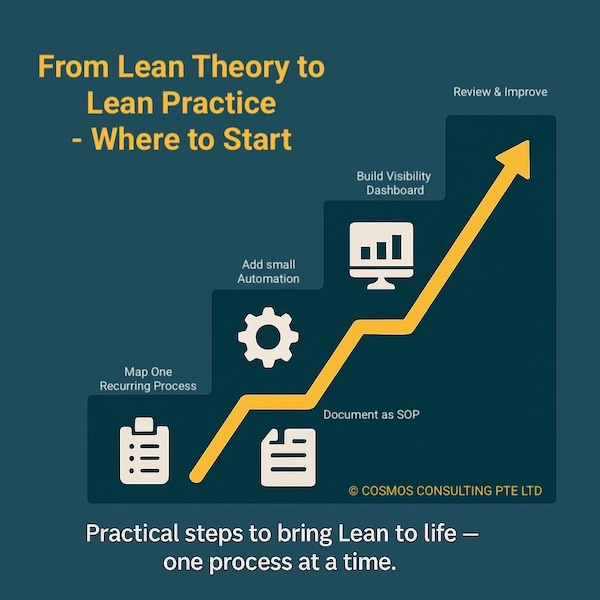

6️⃣ From Lean Theory to Lean Practice – Where to Start

Start small:

- Pick one recurring process (like order fulfillment or quotation prep).

- Document it as an SOP.

- Add a simple automation or visibility tracker.

You will notice the results of Lean for SMEs: less chaos, fewer follow-ups, and faster turnaround – all without a single kaizen workshop. The best way to bring Lean for SMEs to life is not through workshops or jargon, but by improving one process from end to end.

Example:

Start with something simple, like your purchase order process. Map the current flow (Structure), document the steps everyone follows (SOP), add one small automation like an approval alert (System), and track turnaround time on a shared sheet (Scale indicator).

Within a month, you will have your first Lean loop: visible, measurable, and self-sustaining. That is how Lean stops being a theory and becomes a rhythm.

👉 If you missed Part 1, read How to Run Lean Team Operations: SOPs, Automations & Visibility

Next, we will explore why most Lean projects fail in SMEs – and how 4S fixes them.

Conclusion: The Future of Lean is Simpler, and It is the COSMOS 4S Systems Framework™

Lean Thinking gave the world a discipline for improvement.

The COSMOS 4S Systems Framework™ gives SMEs a way to live it – every day, sustainably, without burnout.

Because control is comforting, but clarity is what scales.

Explore More Tools for SMEsGet the SOP Starter Kit & More

Download this and other free templates from the COSMOS Resources Vault.

SOP Starter Kit • 4S Checklist • Dual Framework Guide • Ready ReckonersThe COSMOS 4S Systems Framework™ and COSMOS 5R Leadership Framework™ are proprietary tools developed by Chhavi Jain, Director, Cosmos Consulting. The COSMOS Vault™, COSMOS Fieldbook™, and COSMOS Ready Reckoners™ are brand resources of Cosmos Consulting. All rights reserved.

🟡 COSMOS Lean Clarity Series

Part 1: How to Run Lean Team Operations — SOPs, Automations & Visibility

Part 2: Why Lean Thinking Alone Isn’t Enough for SMEs and What 4S Does Better

Part 3: Why Most Lean Projects Fail in SMEs (and How to Fix It)