Introduction: The Vanishing Inventory Mystery

Every SME leader knows the moment:

you walk into the warehouse,

and the numbers on the stock sheet don’t match the shelves in front of you.

The storekeeper swears nothing has gone missing, yet parts, boxes, or tools seem to evaporate.

It is not theft in the obvious sense.

It is not negligence either.

It is the Inventory Trap – a silent leak that drains time, money, and trust.

Inventory control in SMEs is not just about counting stock; it is about preventing the hidden leaks that derail growth. For manufacturing and service-based businesses alike, the real risk is not missing items; it is broken systems that drag leaders back into firefighting instead of scaling. That is why effective inventory control requires clear structure, SOPs, and systems – — supported by the right inventory control software for SMEs

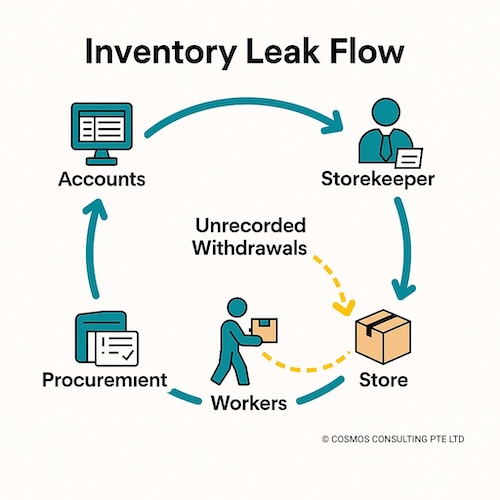

Why Inventory Control in SMEs Often Fails

Despite having a dedicated storekeeper or warehouse clerk, inventory often slips through the cracks. Here is why inventory control in SMEs is so often challenged:

- Informal Withdrawals

Workers take items directly from the store “just to get the job done,” bypassing the storekeeper. One missing washer today becomes ten tomorrow. - No Paper (or Digital) Trail

Without issue vouchers, digital slips, or signatures, there is no way to track who took what and for what. Verbal notes vanish faster than the stock. - Storekeeper as Single Point of Failure

If one person holds all the knowledge, then absence, turnover, or even bias makes the system collapse. - Disconnected Accounts and Warehouse

When finance updates purchase records but logistics tracks usage manually, the gap between systems becomes a black hole where inventory disappears. - Culture of Blame vs. Visibility

Staff fear being accused of mistakes, so they avoid raising issues. Instead of early warnings, leaders get late-stage surprises.

The Real Cost of Weak Inventory Control in SMEs

Inventory leakage looks small in the moment – a missing part worth a few rupees. But the cumulative effect is massive:

- Cash Flow Drain: Small leakages add up to lakhs annually, directly reducing margins.

- Leader’s Time Wasted: Instead of focusing on growth, leaders end up micro-checking counts.

- Trust Breakdown: Suspicion grows between storekeepers, workers, and management.

- Operational Delays: Missing items mean production halts or last-minute expensive purchases.

Example: A startup making custom metal fixtures lost nearly 8% of its monthly raw material value because staff borrowed stock without logging it. The founder realized only when a big order was delayed — and cash was already tied up in “invisible” material. This is a textbook case of weak inventory control in SMEs.

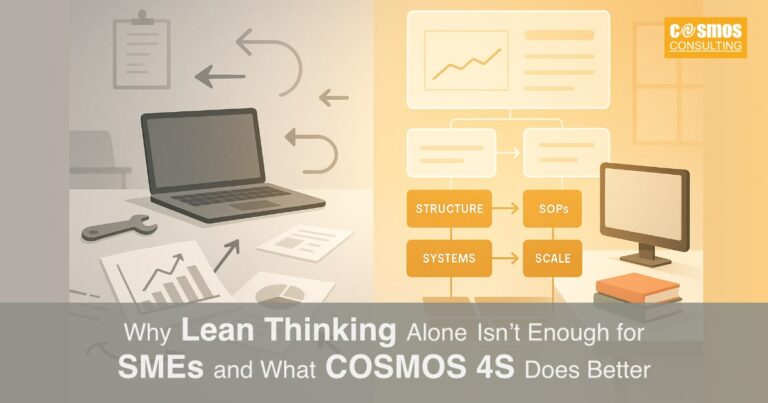

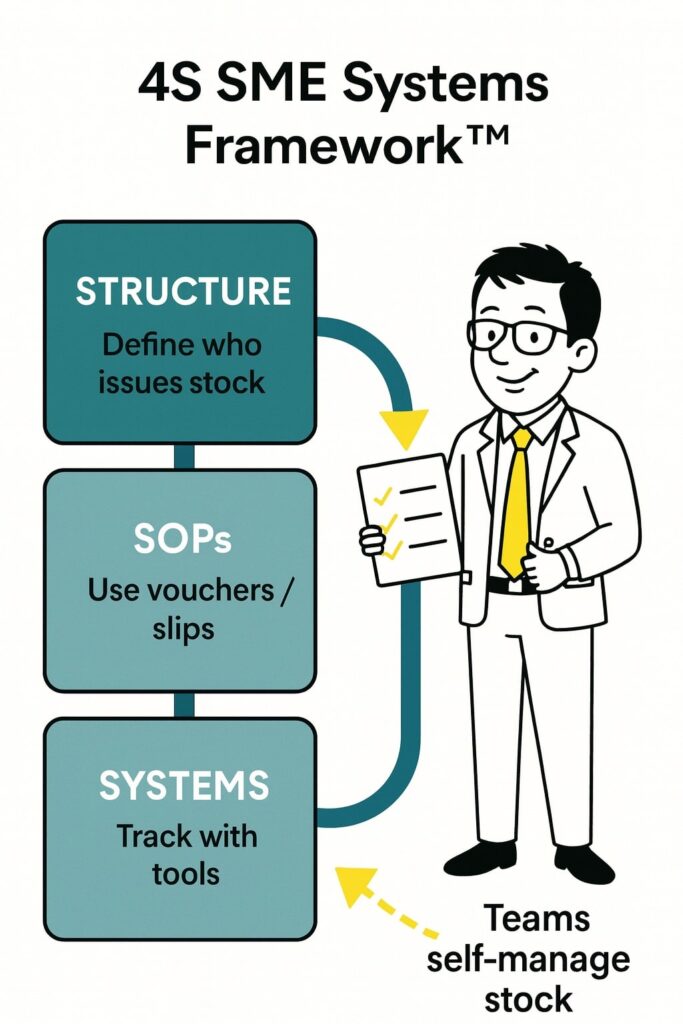

How SMEs Can Fix It: The COSMOS Lens

At Cosmos Consulting, we use the 4S SME Systems Framework™ to tackle exactly these traps. Inventory control in SMEs is a classic case where systems, not individuals, solve the problem.

1. Structure: Define Roles Clearly

- Decide who can and cannot issue stock.

- Train workers that bypassing the process slows everyone down.

- Make the storekeeper the “gatekeeper,” not the scapegoat.

2. SOPs: Put Withdrawals in Writing (or Digital)

- Simple issue vouchers or withdrawal slips for every item.

- Digital options: Google Sheets, simple ERP, or even WhatsApp snapshots of slips.

- SOP = clarity. If it is not recorded, it is not issued.

3. Systems: Use Tools for Visibility

- Even a shared spreadsheet with timestamps prevents most losses.

- For growth-stage SMEs: light ERP or inventory software (Zoho, MYOB, or AppGini-based custom tools).

- Systems connect accounts, procurement, and logistics in one loop.

4. Scale: Create Self-Managing Teams

- Once processes + tools are in place, the leader no longer chases stock.

- Workers understand their responsibility and see the bigger picture.

- Transparency breeds accountability.

Lessons from Other Sectors

- Service SMEs: Consultants lose billable hours when laptops, dongles, or software licenses are “borrowed” without tracking. Same trap, different items.

- Manufacturing SMEs: Spare parts, raw materials, or packaging stock vanish without vouchers.

- Retail SMEs: Seasonal stock gets “adjusted” informally, leading to end-of-season surprises.

Across all cases, the solution is not more policing – it is visibility. And visibility is the foundation of effective inventory control in SMEs.

Reflective Takeaway

The Inventory Trap teaches us something bigger: businesses don’t fail because of dishonest staff, they fail because of invisible systems. When roles, processes, and tools are clear, inventory doesn’t vanish; it moves with purpose. Strong inventory control in SMEs is not about more locks; it is about smarter systems.

Call to Action: Improve Your Inventory Control in SMEs

Have you faced the Inventory Trap in your business? How do you currently track stock: vouchers, spreadsheets, or something else?

Share your struggles or wins in the comments below. Let’s build smarter systems together.

👉 To get started with practical tools for better inventory control in SMEs, explore the COSMOS Process Audit Checklist in the COSMOS Vault. It is a free resource that helps you uncover hidden leaks and blind spots in your operations.