Your team is capable. Your tools are in place. Yet progress feels slow, firefighting never ends, and mistakes keep repeating. Sound familiar?

This isn’t a talent issue. It is the operational visibility for SMEs that is the issue.

Many small and mid-sized businesses operate with invisible gaps in their processes. These gaps don’t show up on dashboards, but they silently drain efficiency, accountability, and growth.

The good news? You don’t need a massive ERP overhaul to fix it. You just need to shine a light on the blind spots.

What Operational Visibility Really Is?

Operational visibility means being able to see how your processes truly function in real-time: from task handovers and timelines to who is responsible for what.

It is not about adding more tools. It is about getting the right information, at the right level, to the right people, exactly when they need it.

Without this clarity, you are managing blindfolded. That is why business process visibility or operational visibility for SMEs is a non-negotiable element of modern operations management.

ERP Readiness Scorecard

Why Operational Visibility for SMEs Matter

Operational blind spots often go unnoticed until problems start stacking up. As businesses scale, small gaps become major slowdowns. Here are a few blind spots commony found in small businesses:

🌀 Busy teams, but slow outcomes: Everyone is working hard, but critical deliverables still fall behind.

🔁 Recurring issues: Problems don’t get resolved at the root. They only get patched.

❓ Role confusion: Teams are not sure who owns what, leading to dropped tasks.

⏳ Delayed decisions: Leaders and managers lack quick insight to act in time.

🎯 Leadership overload: Senior staff end up micromanaging. There is no clarity in the middle layer.

In a manufacturing setup, these operational blind spots can look like:

- Delayed production due to vague procurement timelines

- Frequent firefighting because issues surface too late

- Inventory mismatches stemming from unclear responsibilities

These inefficiencies cost more than time; they lead to missed opportunities, lower morale, customer dissatisfaction, and profit erosion.

Why Visibility Breaks as You Grow?

As the business scales, many layers are added: more people, more tools, more moving parts.

What once worked when five people sat in one room now breaks when fifteen collaborate across locations.

Processes evolve, but if operational visibility for SMEs does not scale with this growth, gaps grow.

Here is the shift:

From informal check-ins → to intentional visibility routines

From clarity by proximity → to clarity by structure

Tools to Improve Operational Visibility for SMEs

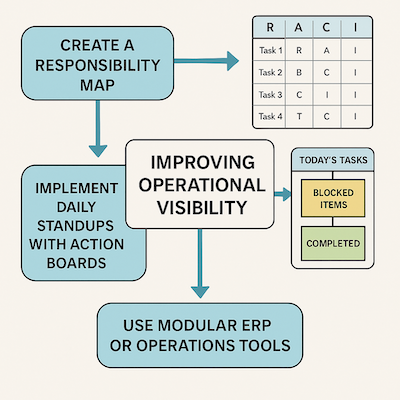

Improving operational visibility for SMEs does not mean investing in a full ERP suite immediately. You can always start small; in fact, it is recommended.

Here are three high-impact changes to get you started:

1. Make Roles and Accountability Explicit

Use a RACI matrix (Responsible, Accountable, Consulted, Informed) for recurring processes. This reduces back-and-forth and avoids dropped balls.

Example: In procurement for manufacturing, define exactly who is accountable for vendor selection, who executes the PO, and who needs to be kept informed.

2. Introduce Lightweight Daily/ Weekly Rhythm

Short, structured check-ins (10–15 minutes) aligned to your workflow can drastically improve clarity. These are not status updates; they are about surfacing blockers.

Example: A daily stand-up across operations and logistics can flag stock shortages before they become emergencies.

This rhythm is key to improving team coordination and reducing response time.

3. Modular Tools, Not Massive Platforms

Start with low-friction tools that give visibility without overwhelming the team.

- Task management: Microsoft To Do, ClickUp, Trello, or Asana.

- Communication: Slack or Microsoft Teams.

- Dashboards: Google Sheets with basic automation can work wonders.

Example: Use a shared dashboard to track open purchase orders, delivery timelines, and responsible owners.

These are excellent tools to achieve better operational visibility for SMEs that have small teams but growing businesses. This concept is part of the COSMOS 4S SME Systems Framework – learn more here. For a deeper understanding of how operational visibility can enhance decision-making, you might find this article on Operational Visibility: Achieving Clarity for Better Decision-Making insightful.

Closing Thoughts

You can’t fix what you can’t see. And in most growing teams, what you don’t see is already hurting you.

Operational visibility for SMEs is not just about efficiency; it is about building a business that scales without chaos.

Start small: define roles, create rhythm, and choose tools that work for your team size.

Once you reduce the fog, you will notice fewer surprises, smoother coordination, and a team that actually enjoys working together.

If you’re ready to make those blind spots visible, we are here to help.

How Does Your Business Ensure Operational Visibility?

Every SME faces unique challenges in maintaining transparency across operations. We would love to hear your experiences:

- What tools or strategies have you implemented to enhance visibility?

- Have you encountered any unexpected benefits or challenges?

Get the ERP Readiness Scorecard & More

Download this and other free templates from the

COSMOS Resources Vault.

SOP Starter Kit • 4S Checklist • Dual Framework Guide • Ready Reckoners

💬 Share your insights in the comments below. Your experiences could provide valuable perspectives for fellow readers.

For a deeper understanding of how we assist SMEs in achieving operational excellence, explore our About Us page.

If you found this article helpful, explore more insights in our blog section.