Introduction

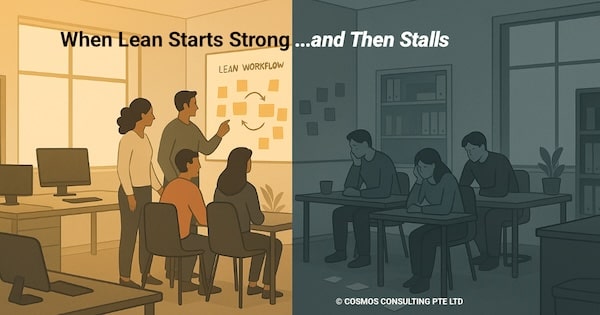

Lean Thinking promised a world of smarter, faster, waste-free businesses. And at first, Lean implementation in SMEs often begins with energy: teams are excited, whiteboards are filled, and managers are talking about “Kaizen” and “5S.”

But six months later, the energy fades. Dashboards stop updating. Daily stand-ups turn into weekly reminders. The “Lean champion” quietly moves back to regular work.

If that sounds familiar, you are not alone. Across hundreds of small and medium enterprises (SMEs), the story repeats: Lean begins as a philosophy and ends as paperwork.

🟡 This post is Part 3 of the COSMOS Lean Clarity Series.

➡ Part 1 (Foundations): How to Run Lean Team Operations — SOPs, Automations & Visibility

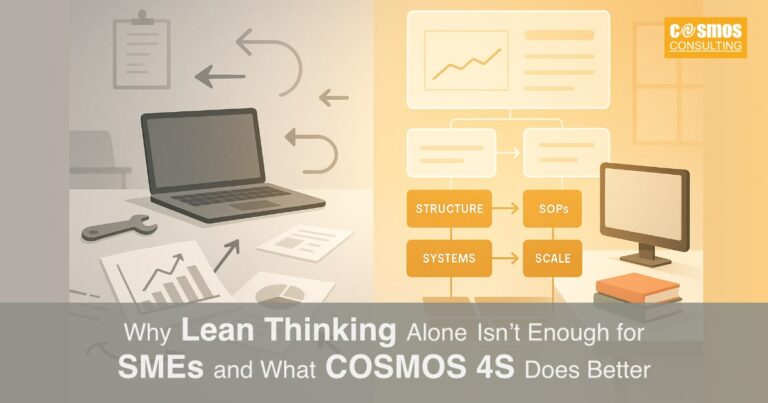

➡ Part 2 (Reframe): Why Lean Thinking Alone Isn’t Enough for SMEs — and What 4S Does Better

1️⃣ Lean Is Not Broken… Implementation Is

According to the Lean Enterprise Institute, Lean is about delivering value with less waste and more flow. Lean sure works… Toyota proved that decades ago. The problem is not the method; it is the context of Lean implementation in SMEs.

Large organisations use Lean on top of strong operational foundations: clearly defined roles, stable SOPs, and measurable systems. SMEs often try to implement Lean without those foundations… skipping straight to improvement before stabilising operations.

I have seen it too many times: teams map value streams before knowing who is accountable for each step. They run Kaizen workshops before daily work is even standardised.

Lean doesn’t fail because teams don’t care… it fails because Lean implementation in SMEs often begins at the wrong place.

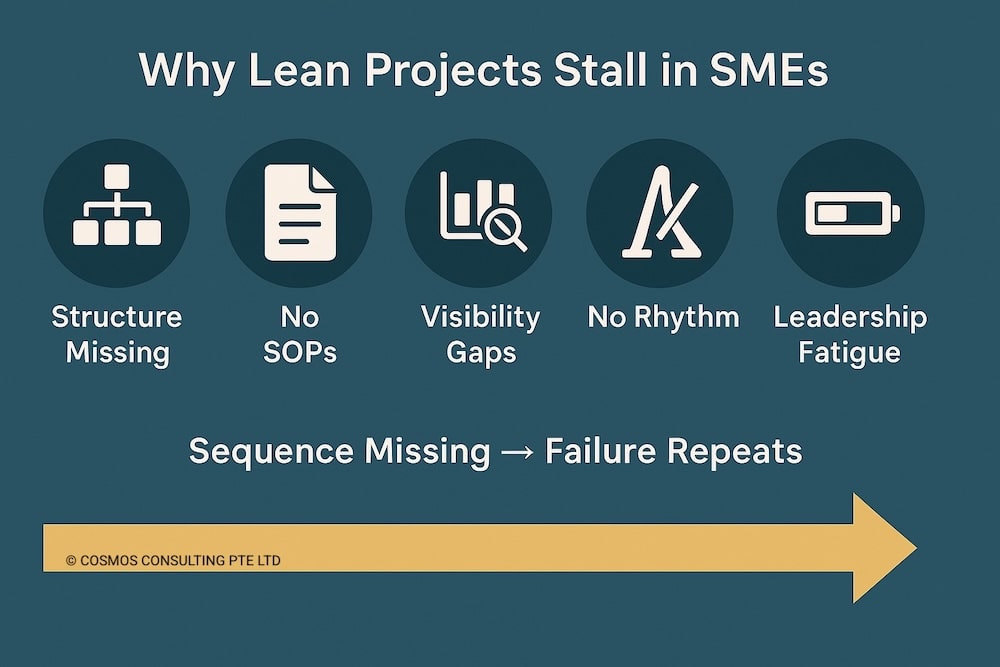

2️⃣ Why Lean Projects Stall in SMEs

Here is what typically happens when small teams try to “go Lean.”

1. No Structural Backbone

Everyone wears multiple hats. The same person approves purchases, manages stock, and handles dispatch.

When everything belongs to everyone, ownership disappears.

“Continuous improvement” cannot exist when it is no one’s clear responsibility.

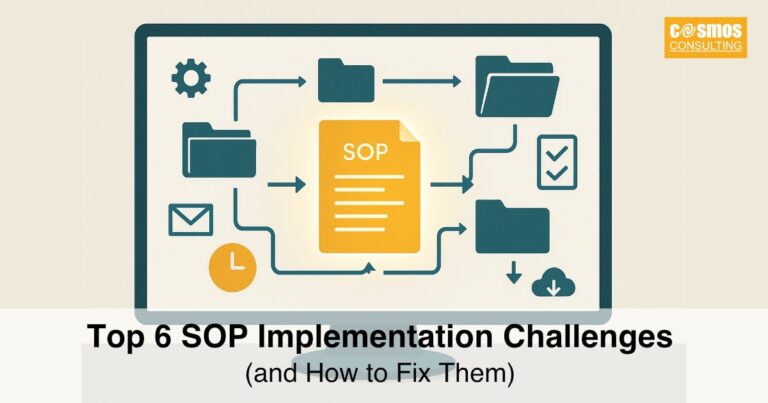

2. No Documented Workflows

Lean thrives on visibility… seeing where waste occurs. But most SMEs don’t have documented SOPs.

So they rely on habit and memory, not process.

Without that baseline, Lean implementation in SMEs quickly becomes inconsistent.

3. Visibility Gaps

Data lives in spreadsheets, WhatsApp messages, or someone’s head.

That means issues are found reactively, not proactively.

You cannot improve what you cannot see.

4. No Improvement Rhythm

Lean depends on cadence, daily stand-ups, weekly reviews, and quick problem-solving loops.

In SMEs, operational firefighting replaces rhythm. Teams are too busy keeping up to look back.

5. Leadership Fatigue

Founders start excited but soon realise Lean needs consistency, not just inspiration.

Without systems to support them, they end up pushing harder instead of smarter… until motivation drops.

These are not failures of discipline. They are failures of sequence, trying to optimise before stabilising.

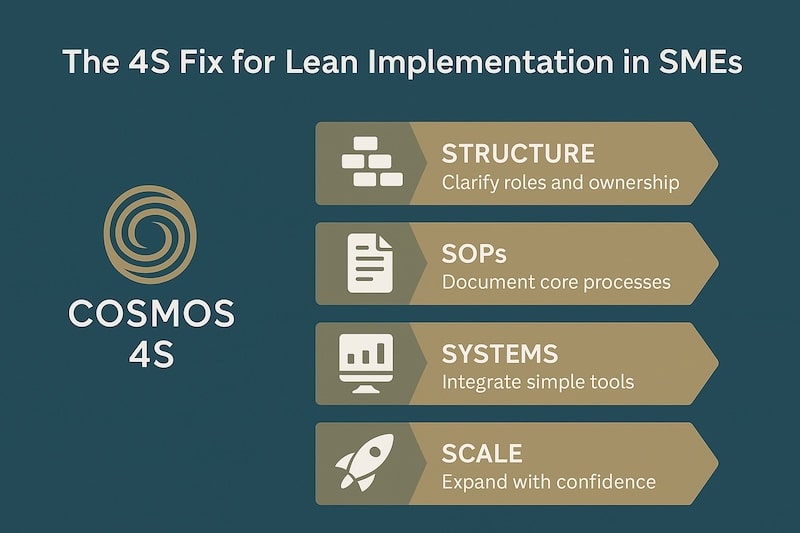

3️⃣ How the COSMOS 4S Systems Framework™ Fixes Lean Implementation in SMEs

Lean gives us the “what”: flow, value, and continuous improvement.

The COSMOS 4S Systems Framework™ gives SMEs the “how.”

It is not a replacement for Lean; it is the scaffolding that makes Lean implementation in SMEs sustainable. It adds back what most Lean rollouts skip… structure and visibility first.

| Common Lean Breakdown | 4S Fix | Outcome |

|---|---|---|

| No ownership | Structure | Roles and visibility clarified |

| No baseline process | SOPs | Standard work makes improvement measurable |

| No visibility | Systems | Simple dashboards, trackers, automations |

| No sustainability | Scale | Continuous improvement becomes self-running |

Before you “go Lean,” go 4S.

Because once structure, clarity, and rhythm are in place, Lean tools finally have a place to land.

📂 Fix your Lean implementation at the root.

Most Lean projects fail because teams are guessing. The SOP Starter Kit gives you the baseline structure your team can execute tomorrow morning.

Get the free Cosmos Vault Kit →

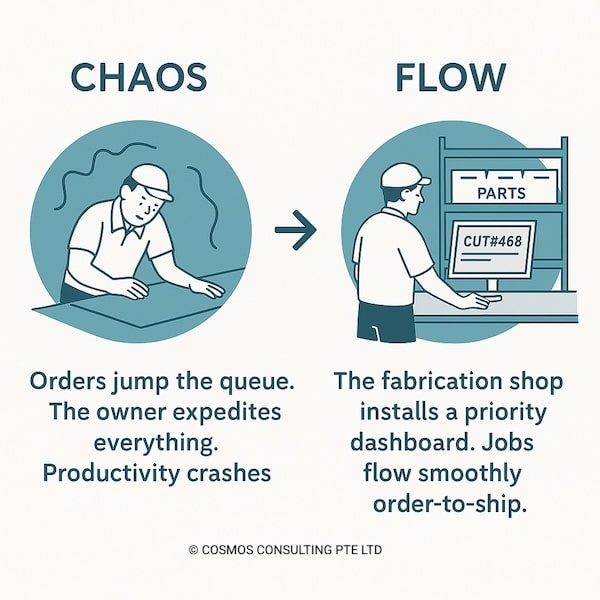

4️⃣ A Real-World Example: When Improvement Finally Stuck

A few years ago, we collaborated with a 15-person fabrication company that had made significant investments in Lean. They had consultants, charts, and weekly 5S audits. But nothing changed. Tools kept shifting, reports piled up, and supervisors were exhausted.

Instead of adding more Lean tools, we applied the 4S sequence first.

We started with Structure: who owned each cell, who approved changes, and who tracked outcomes.

Then, we documented SOPs for basic daily setups.

Next, we used a simple shared system – a Google Sheet dashboard- to track the production flow.

Within a month, the same team saw visible improvement:

- WIP reduced by 18%

- Audit scores stayed consistent without supervision

- Meetings are shortened from one hour to fifteen minutes

They didn’t abandon Lean… they finally made Lean implementation in their SME work.

Lean tools were not the problem; they just needed the right order to take root.

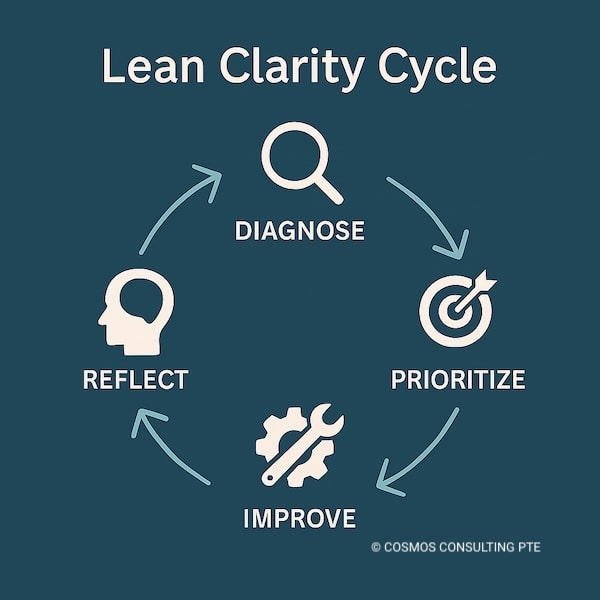

5️⃣ From Failure to Flow: What SMEs Can Learn

Most Lean projects in SMEs fail quietly. Not because the principles are wrong, but because the foundations are missing.

But the good news is that once those foundations exist, improvement becomes self-sustaining.

Start with one department or one recurring workflow.

➤ Map who owns it (Structure),

➤ Document what happens (SOP),

➤ Build visibility (System), and

➤ Track results over time (Scale).

You will notice that Lean implementation in SMEs starts to feel less like a “project” and more like a habit.

That is what Lean was always meant to be.

Conclusion: Lean Works When Systems Do

Lean doesn’t need more consultants or more workshops – it needs better sequencing.

For SMEs, that sequencing is Structure → SOPs → Systems → Scale.

When those layers are in place, Lean implementation in SMEs stops being an aspiration and becomes an operating rhythm.

And that is the real fix: clarity before control, visibility before velocity.

Get the SOP Starter Kit & More

Download this and other free templates from the

COSMOS Resources Vault.

SOP Starter Kit • 4S Checklist • Dual Framework Guide • Ready Reckoners

🟡 COSMOS Lean Clarity Series

Start from the beginning:

➡ Part 1: How to Run Lean Team Operations — SOPs, Automations & Visibility

Then read the mindset shift:

➡ Part 2: Why Lean Thinking Alone Isn’t Enough for SMEs — and What 4S Does Better