Introduction: SME Blind Spots

“Everything seems fine.”

“No one’s complaining.”

“Everyone knows what to do.”

If you are an SME solopreneur, a founder, or operations lead, you have probably told yourself one of these things. And why wouldn’t you? On the surface, things look okay.

But here is the hard truth:

Most SME problems don’t start with chaos.

They begin with silence.

At Cosmos Consulting, we have seen this pattern across industries:

- Teams working around issues instead of fixing them

- Leaders miss signals that are not loud (yet)

- Structure in place, but clarity still missing

This blog is about those moments – the SME blind spots that feel small until they cost you big. And yes, they are avoidable if you know what to look for.

🔹 OPERATIONAL TRUTH #1:

Silence is not a Signal of Success

“No one is complaining, so it must be working.”

That silence?

It could mean that people are coping, rather than thriving. When there is no system to flag issues early, people default to avoidance or quiet workarounds. These silent SME blind spots are often mistaken for stability.

🪧 What it looks like:

- Staff not raising delivery issues

- Errors fixed silently by one person again and again

- Nobody talks about a broken process because “that’s how it’s always been”

✅ Fix it:

Build visibility. Create space for issues to surface without blame.

If you don’t hear it, you can’t fix it. SME blind spots thrive in silence.

🔹 OPERATIONAL TRUTH #2:

Doing Everything = Doing Nothing

“We’ll fix it all — now!”

The problem?

When you try to fix everything, you actually fix nothing. Without prioritisation or ownership, teams start strong and end nowhere. This leads to operational inefficiencies that compound over time.

🪧 What it looks like:

- Five parallel improvements with no one following through

- People unclear on which problem matters most

- Firefighting mindset even when there’s no fire

✅ Fix it:

Tackle one issue at a time. Assign it with clarity.

Take it to the finish line before moving on.

The path to solving dysfunction is built one focused step at a time.

🔹 OPERATIONAL TRUTH #3:

Strategy That Cancels Strategy

Meeting 1: Approve Strategy A

Meeting 2: Greenlight Strategy B (which contradicts A)

Sound familiar?

This is what happens when decisions are made in silos or without checking how one plan impacts another. Many SMEs fall into this trap, confusing action with alignment.

🪧 What it looks like:

- SOPs created in one meeting, replaced in the next

- Solutions that solve one issue but create two more

- Staff unclear which rules apply today

✅ Fix it:

View strategy in totality.

Solve with context, not patches.

A solution that breaks another process is not a solution; it is a delay. And delays are what quietly stall growth.

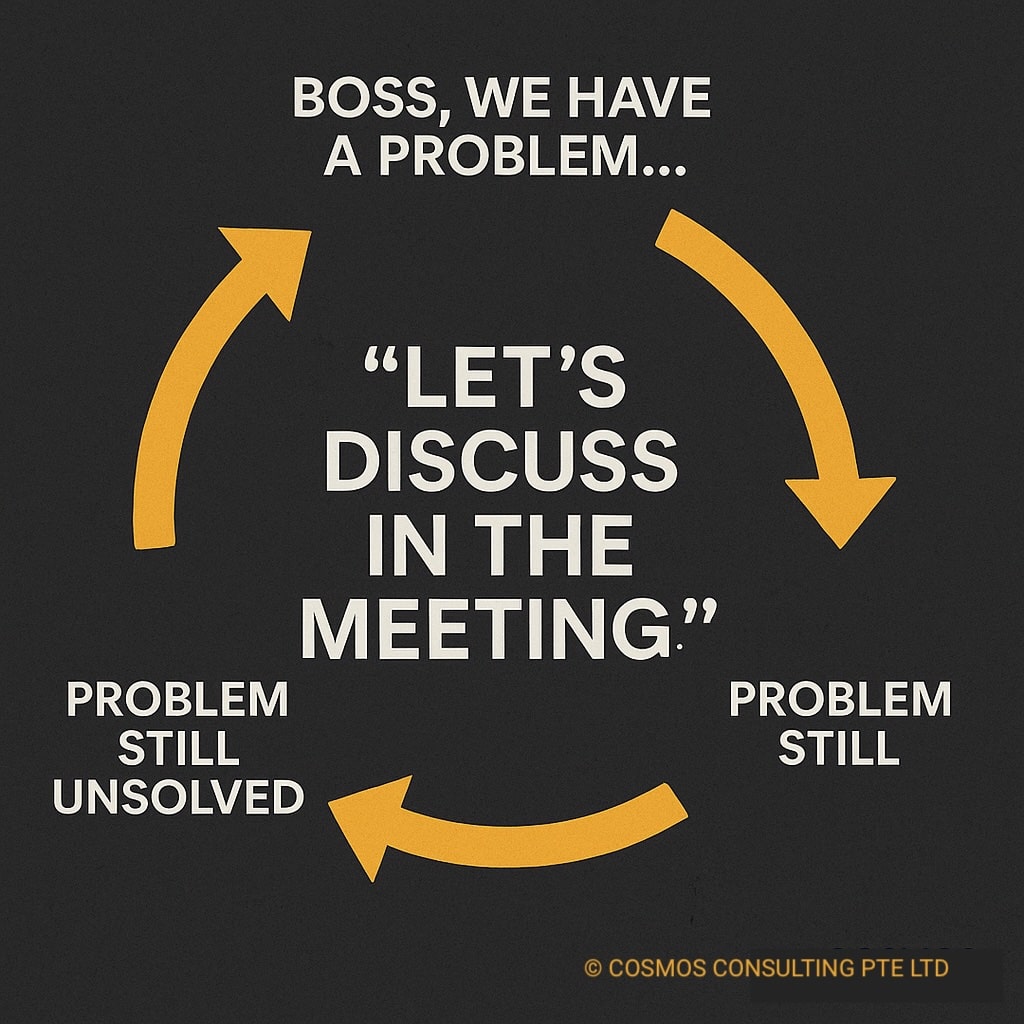

🔹 OPERATIONAL TRUTH #4:

“Let’s Discuss in the Meeting” Is NOT a Fix

Problem → Meeting postponed → Agenda lost → Problem resurfaces

If every issue loops back to a vague future meeting, you’re not managing problems; you are rescheduling them. This creates slow, creeping dysfunction that no one owns.

🪧 What it looks like:

- Calendar full of meetings but no decisions made

- No agenda, no closure, just repetition

- Same issue raised 3 weeks in a row

✅ Fix it:

Make meetings tighter. Declare the agenda in advance.

Close each loop fully before moving to the next.

This is the foundation of execution clarity.

🔹 OPERATIONAL TRUTH #5:

Start With the Basics (Yes, Really)

Everyone is throwing big ideas around.

Then someone says, “Wait… but did we even…”

And silence.

Often, the solution isn’t new tech or process maps. It is fixing the basic step everyone is ignoring.

🪧 What it looks like:

- Teams missing a simple approval step

- Complicated automations failing due to one skipped action

- Staff unclear on what “success” actually looks like

✅ Fix it:

Slow down. Map the process. Ask the “naive” questions.

You will be surprised how many answers live in “THE OBVIOUS”.

🔎 How These Blind Spots Show Up in Real SMEs

In one SME we worked with, the finance team kept missing invoice deadlines. The founder thought it was laziness. But the truth? There was no shared tracker. Each person had their own system. Once we implemented a visible dashboard and one SOP, errors dropped by 90%.

In another case, a staff member was bypassing a crucial QC step because “no one checks anyway.” That one missed detail cost the company a major client.

These are not rare events. They are everyday blind spots.

🔧 What to Do Next (Before It Spirals)

If you’re seeing some of these signs in your team, don’t panic… act.

✅ Review your workflows. Where is clarity missing?

✅ Ask your team what frustrates them silently.

✅ Prioritise one system to fix this month.

As this HBR article on noise and hidden inconsistencies points out, most business inefficiencies are not dramatic; they are quiet, frequent, and expensive.

And if you want to systemise things before they break…

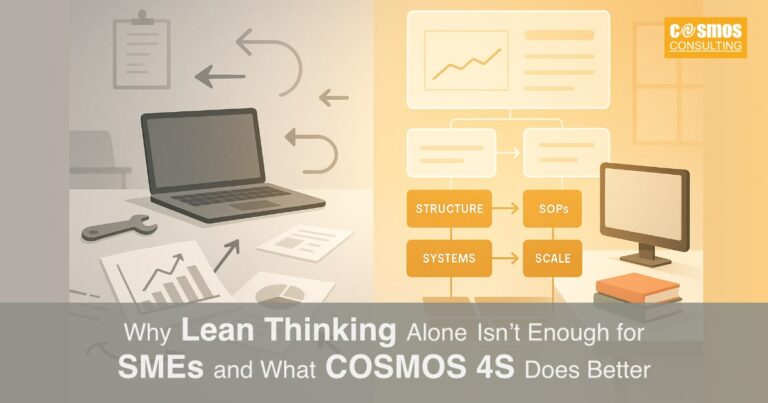

🔄 From Truths to Systems — And Beyond

These operational SME blind spots are not just observations; they are warning signs.

If you have noticed any of them in your own business, it is not a red flag… yet. But it will be.

The good news? These blind spots are all solvable. But only if you see them before they spiral.

📌 If you are still solving the same problems repeatedly, it may be time to systemise for good.

Start with the COSMOS 4S Systems Framework™. It’s your staff-side clarity foundation.

But if you have already built systems, and the stuckness remains…

Then maybe it is not the structure. Maybe it is what the leader is not seeing.

🖐️ Visit: The COSMOS 5R Leadership Framework™ ➤ ➤ for founders ready to lead with visibility… not just instinct.

Fix this in your business today → Download the free Process Audit Checklist