💬 Introduction: It is Not Always Broken. Sometimes, It is Just Leaking.

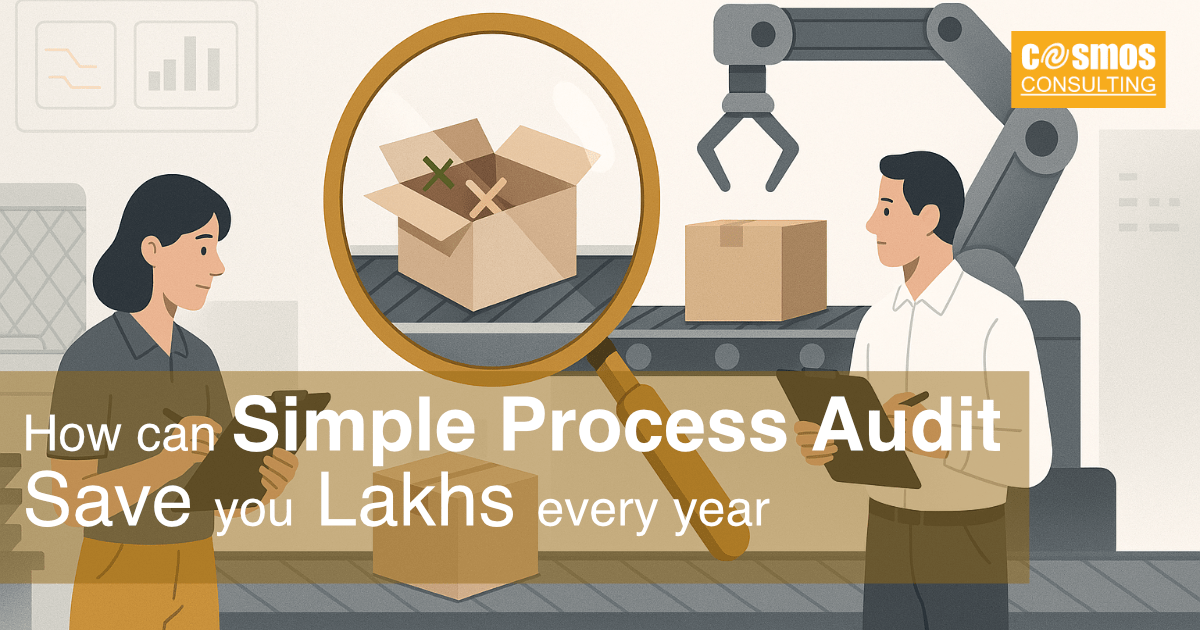

Most small and mid-sized businesses don’t realize they’re losing money every single day; not because of a crisis, but because of tiny, repeated inefficiencies that go unnoticed.

👉🏻 Approvals pile up…

🙇🏻 People get frustrated…

🏃🏻Customers leave quietly…

And somehow, no one knows why. 🤷♂️

This is where a process audit comes in, not to catch mistakes, but to help you see your operations clearly, maybe for the first time.

🤔 What is a Business Process Audit in Simple Words?

Think of it as a map of how your business really works.

NOT how it should work.

NOT how your team says it works.

But how it ACTUALLY works… day to day.

A process audit is a structured review of your core workflows, across various functions like:

- Sales

- Operations

- Procurement

- Customer support

- Accounts & Finance

It involves observing tasks, interviewing teams, mapping workflows, identifying delays or overlaps, and then recommending practical improvements and defining SOPs where required.

It is not a compliance check.

It is a clarity tool.

Process Audit Checklist

10 quick checks to uncover hidden inefficiencies and cut costs.

🚧 How Operational Inefficiencies Show Up in Daily Business Life

Operational inefficiencies might seem like minor inconveniences: missed emails, delayed handovers, duplicated work, but they add up fast. A Statista study found that businesses lose significant revenue annually due to avoidable process inefficiencies, highlighting just how costly these everyday issues can be.

You may not notice them… but here is how process gaps sneak in the business:

1. Sales Orders Are “Stuck” Until Someone Notices

No formal tracking system? Then you are relying on memory.

By the time someone realizes an order hasn’t moved, it’s already late.

2. Too Many Approvals, No Accountability

Sometimes, 3-4 people need to “approve” a simple vendor invoice.

But who is actually responsible? Nobody knows. Meanwhile, delays happen.

3. Work Depends on One Person’s Knowledge

“Only Ravi knows how that works.”

What happens when Ravi is on leave? Chaos.

4. Manual Work Repeated in Multiple Places

Same customer data entered in Excel, then in billing software, then emailed again.

Wasted effort. High risk of error.

5. No Feedback Loop When Things Go Wrong

An error happened, it was fixed, but…

Nobody analyzed it. So it will happen again.

Sound familiar? Let me explain more with some case studies:

🏭 Case Study 1: Manufacturing – Invisible Delays, Real Costs

A mid-sized manufacturer in Malaysia was struggling with slow dispatch.

Deliveries were late, customers were complaining, and internal friction was growing.

They thought it was a vendor issue.

It was not.

After mapping their full “Order to Dispatch” process, it was found that:

- Sales was entering orders manually in two tools.

- Stores was unaware of urgent orders due to no tagging system.

- Transport approvals were dependent on one person’s daily availability.

👷🏻 The fix?

- One shared dashboard

- Priority labels added to sales orders

- Alternate approver logic for dispatch

🤩 Result?

- 27% faster average dispatch

- 40% fewer customer complaints in 2 months

- Estimated annual cost reduction: USD 6,000-7,000/-

🧑🤝🧑 Case Study 2: NGO – Volunteer Onboarding Turnaround

A Delhi-based NGO with a noble mission… but an overloaded process.

New volunteers were waiting 2–3 weeks to get assigned. Some never showed up again.

An audit was conducted and it revealed that:

- The onboarding steps were not documented.

- The same person was managing three unrelated tasks.

- Volunteer data was collected by phone, then manually typed.

A few changes listed below were implemented as per the suggestions offered:

- SOPs were created for onboarding.

- Workload was rebalanced.

- A free online form + auto-email system replaced the manual entry.

🤩 Result?

- Volunteer activation time dropped to 5 days.

- Volunteer retention increased by 2x.

- Admin time reduced by 12–15 hours per month.

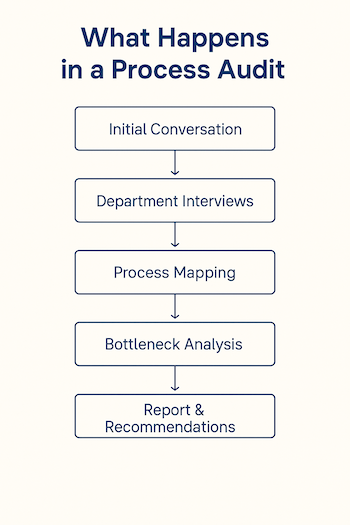

🔎 How is Business Process Audit carried out, or what exactly does it entail?

Every consultant may do it differently, but a typical cost audit includes:

- 🗺️ Mapping how your current processes really work.

- 🧠 Interviewing staff to understand day-to-day challenges.

- 🕵️♂️ Identifying bottlenecks and inefficiencies.

- 📊 Analyzing metrics (if available) or tracking time manually.

- 🛠️ Recommending improvements, quick wins, and long-term changes.

Think of it as building a mirror for your business.

The insights are often surprising and empowering.

🧩 Where Can You Start?

Here is a quick starter checklist:

| Area | Ask Yourself… |

|---|---|

| Sales | How are leads tracked? Who follows up? How fast? |

| Operations | Where do most delays occur? Who owns what? |

| Finance | Are payments delayed due to unclear approvals? |

| Support | What issues repeat most? Are root causes analyzed? |

| HR | Is onboarding consistent? Who trains new staff? |

💬 Final Thoughts

If you are unsure about the answers, you probably need a map.

A process audit isn’t about being perfect.

It’s about getting visibility.

And when you see things clearly, you can fix them easily.

No expensive tools.

No 6-month transformation plans.

Just clarity.

And with clarity, comes solutions and with solutions comes control.

A well-timed process audit can transform inefficiency into opportunity.

Business Process Audit Checklist

10 quick checks to uncover hidden inefficiencies and cut costs.

💬 What Did Your Last Cost Process Audit Reveal?

Or… have you ever actually done one?

We would love to hear your thoughts, whether you are in operations, leadership, or just obsessed with how things tick behind the scenes.

💭 Drop a comment below or share this with someone who’s always firefighting at work.

This really hit home—we recently did a mini audit and found three steps we could completely eliminate. Saved us hours each week!